Table of Contents:

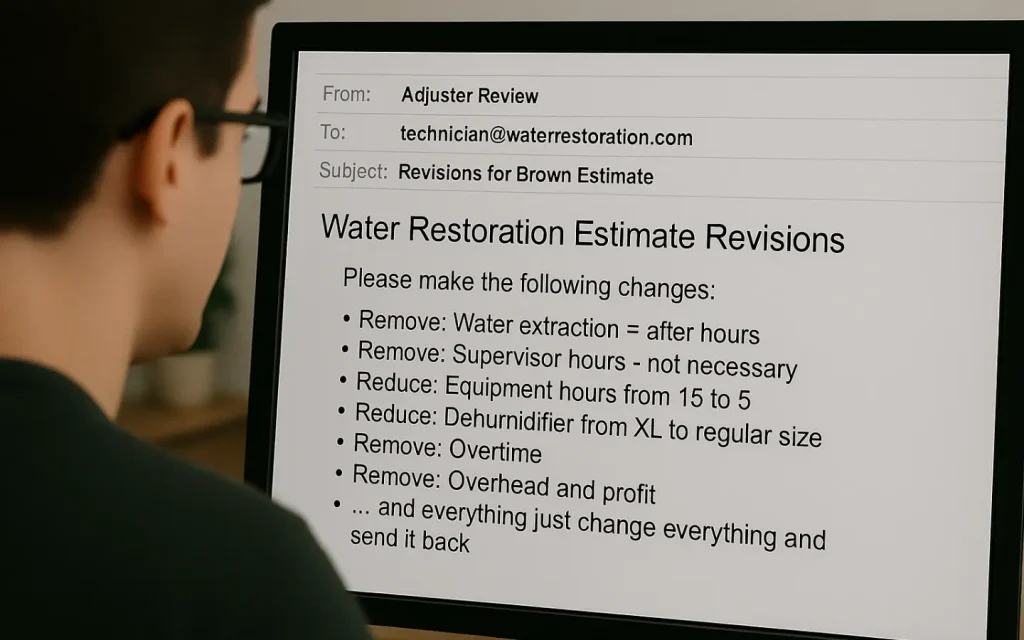

Every restoration professional has been there: you run a textbook drying project, document everything meticulously, but get denied payment when a reviewer questions your dehumidifier charges due to low grain depression numbers.

Here’s how to prevent this from happening in the future:

Why Reviewers Are Getting It Wrong

Declining grain depression readings in the later stages of a project signal effective moisture removal, not equipment failure.

When structural materials reach their dry standard, they release less moisture into the air, naturally resulting in a smaller difference between inlet and outlet air measurements.

The industry’s current fixation on maintaining high grain depression numbers throughout the entire project actually contradicts the natural drying process.

Practical Steps to Secure Payment

The solution lies in strategic documentation and equipment placement. When grain depression readings fall below the typical five-grain threshold, conduct a thorough inspection of areas farther from the dehumidifier location. For example, if a Bedroom and a Bathroom are affected, take readings in the Hallway and perhaps one of the unaffected Bedrooms.

These measurements often reveal higher GPP readings in other parts of the structure. Document these findings, relocate the dehumidifier to address these areas, and maintain detailed records of your decision-making process.

Learn how to place the right amount of LGR dehumidifiers on the ReetsTV platform.

Documentation That Ensures Payment

Your daily monitoring reports require specific data points to justify equipment charges, so you should record initial baseline readings across multiple areas of the structure.

Also, track the progressive reduction in moisture content of affected materials alongside your grain depression measurements.

And most importantly, when documenting equipment placement decisions, include moisture readings both near and far from the dehumidifier, specifically identifying areas that still show elevated GPP readings – these numbers create the concrete justification for continued equipment deployment.

The ReetsTV platform shows you exactly how to document drying conditions so you get paid.

Making Your Case to Reviewers

You should always clearly outline the progression of the drying process when submitting documentation.

Show how initial high grain depression readings transitioned to lower numbers as materials dried, emphasizing that this pattern reflects successful moisture removal rather than diminished equipment effectiveness.

Include material moisture readings that demonstrate the continuing need for dehumidification despite lower grain depression numbers.

Proactive Communication Strategies

Don’t wait for payment denial to make your case.

Establish early communication with adjusters about your drying approach. Explain that grain depression will naturally decrease as materials dry, and outline how your equipment placement strategy maximizes drying efficiency throughout the entire process, so you prevent any issues before they arise.

Securing payment requires precise documentation of moisture readings across multiple locations (not just grain depression measurements), so you should use these data points to demonstrate equipment placement decisions and validate charges through the final stages of drying.

Just remember: Reviewers need to see the full picture, not just single-point measurements. A well-documented project that demonstrates thoughtful equipment deployment decisions will secure payment even when grain depression numbers fall below traditional thresholds.

ReetsTV gives you the training you need to do the job right and get paid.

770-712-7293